More than 60% of cargo tank rollover accidents occur when tanks are carrying partial loads. This is due to the slosh and surge effects caused by liquid loads, particularly when the tank is not full. Slosh changes the tanker’s centre of gravity as the liquid runs up its sides, while surge impacts vehicle stability as the liquid shifts from front to back during acceleration and braking.

Many truck accidents stem from overbalancing issues caused by liquid surge problems and sudden steering changes. Drivers often have to swerve to avoid traffic hazards, leading to load imbalance and vehicle drag. While some crashes result from human error, many are preventable with strict safety measures. One crucial measure is an advanced surge system for heavy vehicles transporting liquids. 1.

Understanding the Importance of Surge Systems

Tank drivers understand the critical role of an effective surge system. Surge systems absorb the force of liquid sloshing inside the tank, particularly during braking or stopping. They distribute the liquid’s weight evenly, preventing imbalance and potential rollovers. Surge systems not only enhance safety but also reduce wear and tear on the vehicle’s brakes.

Issues with Traditional Surge Systems

Common surge systems, often called ‘baffles,’ include built-in baffles and baffle balls. Both have significant drawbacks.

Limitations of Built-in Baffles

• Welded into the tank and prone to cracking and deterioration, requiring frequent replacements.

• Disrupt the energy of liquid surges but don’t absorb it, leaving a high rollover risk.

Challenges with Baffle Balls

• Intricate and time-consuming to assemble.

• Can be flat-packed when not in use but risk unclipping if the tank is filled too quickly, leading to unsafe liquid surges.

Introducing the Baffle Bone: Our Solution

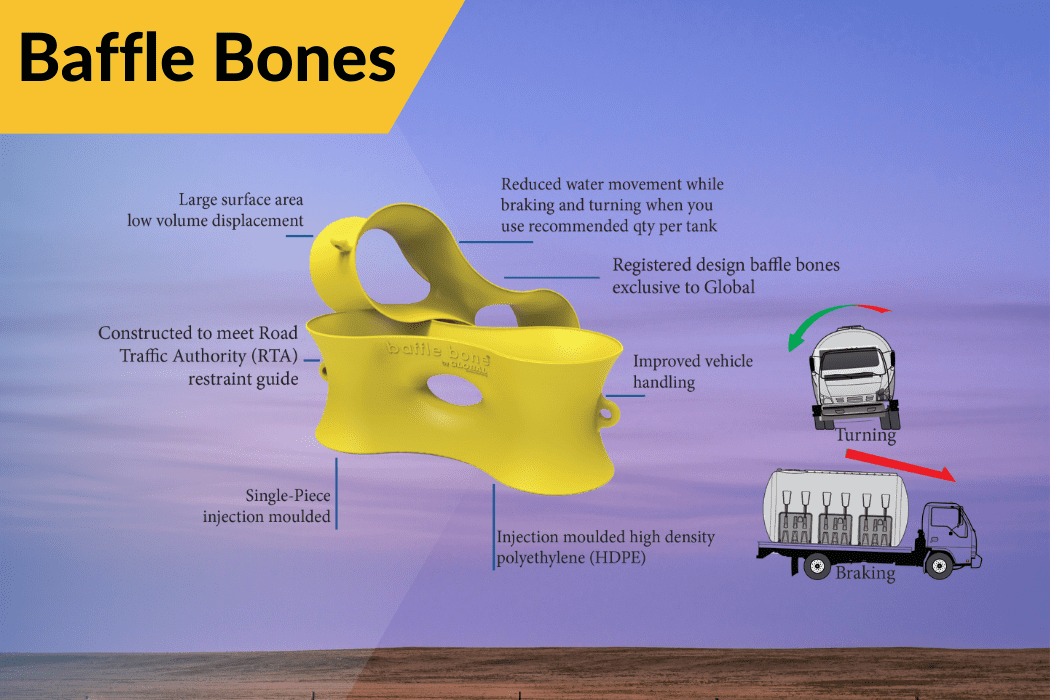

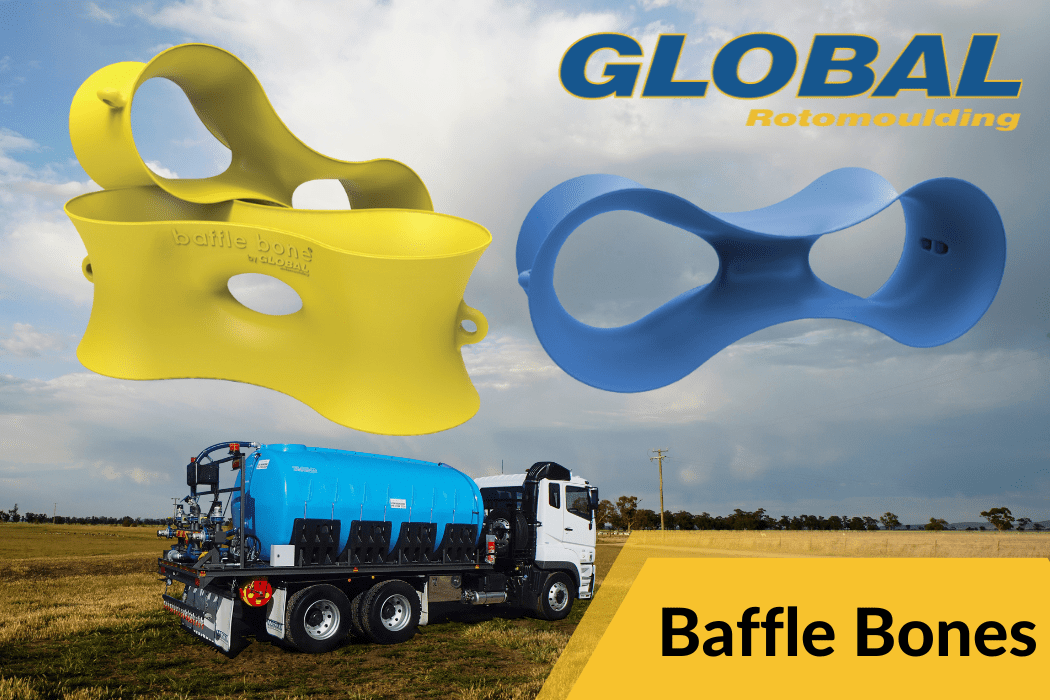

Considering these issues, Global developed a superior baffle system— the Baffle Bone. Here’s why the Baffle Bone is the ultimate surge system for road tankers:

Enhanced Durability

• Constructed from robust, low-density polyethylene, ensuring longevity for decades.

• Seamless roto-moulded design with no joints eliminates the risk of cracking.

Improved Safety

• Reduces brake strain and evenly distributes and absorbs energy from liquid surges, minimizing rollover risk.

Unmatched Versatility

• Suitable for a wide range of hot or cold chemicals.

Superior Hygiene

• Does not retain water and is easy to clean, preventing substance cross-contamination.

Certified and Tested

• Independently tested and certified to meet the Load Restraint Guide.

Cost-Effective Production

• Made from plastic, with an existing mould, making them easy and economical to produce and purchase.

Small Baffle Bone

Dimensions: 420 x 150 x 150 mm

Surface Area (SA): 0.289 m²

Approx Weight: 0.33 kg (based on 2.5 mm nominal wall in LLDPE)

Approx Displacement: 0.35 L (based on 3 mm nominal wall)

Boundary Volume: 9.45 L

Large Baffle Bone

Dimensions: 700 x 270 x 260 mm

Surface Area (SA): 0.289 m²

Approx Weight: 0.33 kg (based on 2.5 mm nominal wall in LLDPE)

Approx Displacement: 0.35 L (based on 3 mm nominal wall)

Boundary Volume: 9.45 L

Each Baffle Bone features a large surface area and low volume (displacement). This unique shape is a single-piece injection moulded part that is strong enough to withstand the sloshing force of water in a tank and requires no assembly. When many Baffle Bones are used together, the combined high surface area significantly reduces the movement of water within the tank, dramatically improving vehicle handling.

Ensuring Safety for Truckers on the Road

Baffle Bones ensure your vehicle stays balanced and protect you during sudden stops or braking. Global recommends using the Baffle Bone system in vehicle tanks with capacities over 2,000 litres. To find out the number of Baffle Bones your vehicle needs, please visit our detailed guide.

Contact Us

Interested in purchasing a Baffle Bone system for your cartage tank or truck? Contact us today!

References

1. CSTT – Heavy Vehicle Rollover Prevention: How Drivers and Operators Can Avoid HV Rollovers accessed 17.6.2024